If you have a gas furnace or water heater, you should have a sediment trap installed on the gas line. A sediment trap is a small vertical pipe located near the gas appliance that captures any debris or sediment that may be present in the gas line. This is important because sediment can cause damage to the gas valve or burner, leading to malfunctions and even dangerous situations.

Proper installation of a sediment trap is crucial to ensure its effectiveness. The gas line should be configured so that the main flow is vertical, with the tap outlet being horizontal. The gas supply should be connected to the top opening of the tee, while the gas appliance should be connected to the horizontal tap outlet. A nipple should be installed into the bottom opening of the tee and capped. This configuration allows any sediment to settle in the trap and prevents it from entering the gas chamber of the appliance.

It is important to note that sediment traps are required by local plumbing codes for gas appliance installations. Installing a sediment trap can save labor time and reduce leak points, while ensuring compliance with local codes. By understanding the importance of sediment traps and how to properly install them, you can ensure the safety and efficiency of your gas appliances.

Key Takeaways

- Purpose of Sediment Traps: Sediment traps, also known as drip legs or dirt traps, are essential components in gas supply lines for appliances like gas furnaces and water heaters. They capture and collect sediment, debris, and moisture to prevent damage to gas valves and burners.

- Code Requirements: International Residential Code (IRC) and International Fuel Gas Code (IFGC) mandate the installation of sediment traps at all gas appliances to ensure safety and prevent hazardous gas formation.

- Protection Against Hazards: Sediment traps serve as a safety measure to prevent gas leaks, fires, and other hazards that can result from clogs, leaks, and corrosion in gas lines.

- Components of Sediment Trap: A sediment trap consists of components such as a tee fitting, nipple, capped nipple, drip leg, and chamber, all working together to trap and remove sediment from the gas line.

- Installation: Proper installation is crucial, with the sediment trap placed downstream of the appliance shut-off valve and as close to the appliance inlet as possible. Professional installation is recommended for those unfamiliar with gas line installation.

- Maintenance: Regular maintenance is necessary to ensure sediment traps function properly. Sediment should be removed at least once a year, and the trap should be inspected for clogs or damage. Using the right-sized trap and cleaning can prevent clogs.

- Regulations and Codes: Specific codes and regulations, such as G2419.4 and the Florida Building Code, govern the installation of sediment traps. Compliance with these codes is essential to ensure safety and prevent gas leaks.

Understanding Gas Line Sediment Traps

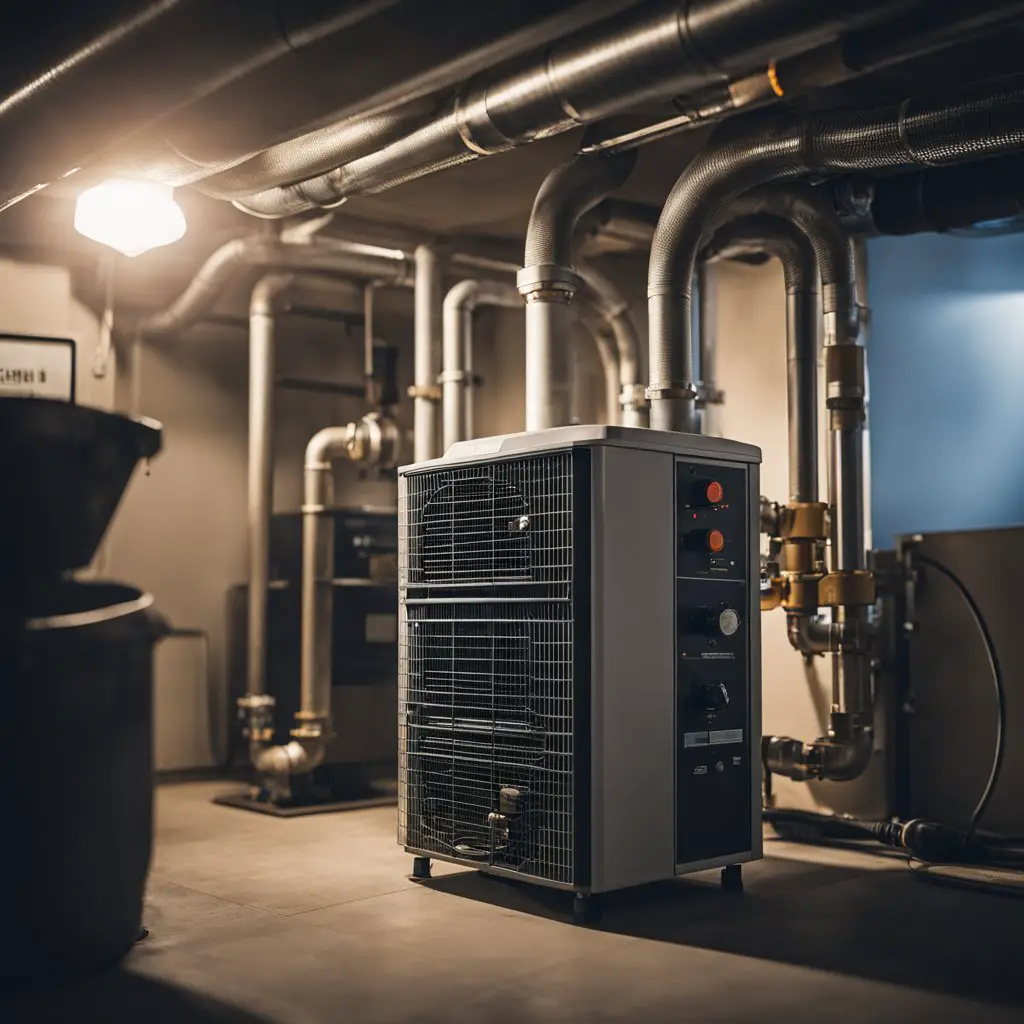

If you have a gas furnace or gas water heater, then you should have a short, vertical gas pipe in front of it. This pipe is called a gas line sediment trap, and it is an essential component of your gas line system.

A gas line sediment trap is a small device installed in the gas supply line of a tankless water heater or gas furnace. It is designed to capture and collect any sediment, debris, or moisture present in the gas line, preventing them from reaching the appliance and potentially causing damage.

Sediment traps are required to be installed at all gas appliances according to the International Residential Code (IRC) and International Fuel Gas Code (IFGC). They are also called drip legs, dirt traps, or drip tees.

Sediment accumulation in gas lines can cause clogs or other issues with operation. It can also lead to the formation of hazardous gases such as methane. This is why sediment traps are crucial in preventing these issues.

Gas line sediment traps are easy to install and maintain. They are typically installed below the gas valve and before the gas line enters the appliance. They are also easy to clean and should be inspected regularly to ensure they are not clogged with debris.

Importance of Sediment Traps

If you have a gas line in your home, it is essential to have a sediment trap installed. Sediment traps serve as a safety measure to prevent gas leaks, fires, and other hazards caused by clogs, leaks, and corrosion.

Gas line sediment traps are designed to capture any sediment or debris that may be present in the gas line before it reaches the gas appliances. This is important because sediment and debris can cause damage to the gas valves, burners, and other components of gas appliances.

Without a sediment trap, the sediment and debris can build up over time, leading to clogs and leaks in the gas line. This can cause serious safety hazards, including gas leaks and fires.

Sediment traps also protect your gas appliances from damage caused by sediment and debris. Over time, sediment and debris can accumulate in the gas line, causing corrosion and other damage to the gas valves and burners. This can lead to costly repairs and replacements of gas appliances.

Installing a sediment trap is an easy and affordable way to protect your home and family from the dangers of gas leaks and fires. It is a simple device that is installed at the gas line’s lowest point, allowing any sediment or debris to settle out of the gas before it reaches the gas appliances.

Components of a Sediment Trap

A sediment trap is an essential component of a gas line that prevents sediment and debris from entering the gas valve or burner area of an appliance. It is also known as a drip leg or dirt leg and consists of several parts that work together to trap and remove sediment.

The following are the main components of a sediment trap:

Tee Fitting

A tee fitting is a T-shaped pipe fitting that connects the gas supply line to the sediment trap. It is installed with the tee tap facing down, and a nipple is attached to the bottom of the tee to create a drip leg. The tee fitting is typically made of brass or copper and is available in different sizes to fit various gas line diameters.

Nipple

A nipple is a short pipe that is threaded on both ends and is used to connect the tee fitting to the capped nipple. It is usually made of black iron or galvanized steel and is available in different lengths and diameters.

Capped Nipple

A capped nipple is a short pipe that is threaded on one end and capped on the other. It is attached to the bottom of the nipple and serves as the collection chamber for sediment and debris. The capped nipple is typically made of black iron or galvanized steel and is available in different lengths and diameters.

Drip Leg

A drip leg, also known as a dirt leg, is a vertical pipe that extends downward from the capped nipple. It is used to collect sediment and debris that may be present in the gas supply line. The drip leg is typically made of black iron or galvanized steel and is available in different lengths and diameters.

Chamber

The chamber is the part of the sediment trap that collects sediment and debris. It is located at the bottom of the capped nipple and is designed to trap and hold any particles that may be present in the gas supply line. The chamber is typically made of black iron or galvanized steel and is available in different sizes to accommodate different amounts of sediment.

Installation of Gas Line Sediment Traps

Installing a sediment trap on your gas line is a wise investment that can protect your appliances and save you money in the long run. Sediment traps are designed to catch small particles of debris that can be present in the natural gas flowing through your pipes.

To install a sediment trap, you will need to follow a few simple steps. First, cut the gas line so that it is below where the sediment trap will be installed. Next, attach a fresh coupling to the end of each section. Tighten it securely using an adjustable wrench or gently tap them together with a brass hammer. If you want to prevent corrosion, you can apply some pipe dope.

It is important to note that sediment traps are required at all gas appliances, except for illuminating appliances such as gas fireplaces and decorative vented appliances. Sediment traps are required to be installed downstream of the appliance shut-off valve and as close to the appliance inlet as possible.

Professional installation is recommended for those who are not familiar with gas line installation. A professional installer can ensure that the sediment trap is installed correctly and that all connections are tight and secure.

Here are a few examples of gas appliances that require sediment traps:

- Ranges

- Clothes dryers

- Outdoor grills

- Water heaters

- Fireplaces

By installing a gas sediment trap kit, you can protect your appliances from damage and prolong their lifespan. Make sure to follow all safety guidelines and regulations when installing a sediment trap on your gas line.

Maintenance of Sediment Traps

To ensure the proper functioning of sediment traps, regular maintenance is necessary. Neglected sediment traps can become clogged, which can lead to gas line problems. In this section, you will learn about the maintenance of sediment traps.

The first step in maintaining a sediment trap is to unscrew the cap and remove any accumulated sediment. This should be done at least once a year or as needed. The sediment should be disposed of properly and not flushed down the drain.

During a home inspection, it is important to check the sediment trap for any signs of clogging. If the trap is clogged, it can cause problems with gas appliances and lead to expensive repairs. A clogged sediment trap can also be a safety hazard.

To prevent clogging, it is important to use a sediment trap that is appropriately sized for the gas line. A trap that is too small will not be able to catch all of the sediment, while a trap that is too large may not allow for proper gas flow.

If you notice any problems with your gas appliances, such as decreased performance or unusual noises, it may be a sign that the sediment trap needs maintenance. In this case, it is best to contact a professional to inspect and clean the trap.

Regular maintenance of sediment traps is essential for the safe and efficient operation of gas appliances. By following these tips, you can ensure that your sediment trap is functioning properly and avoid costly repairs.

Regulations and Codes for Sediment Traps

When it comes to gas line sediment traps, there are several regulations and codes that must be followed to ensure safety and compliance. One of the most important codes to follow is G2419.4, which outlines the installation requirements for sediment traps in gas systems.

The Florida Building Code also has specific regulations for sediment traps, which can be found in Section 408.4. These regulations require that sediment traps be installed in gas piping systems in order to prevent debris and sediment from entering gas-fired appliances.

In addition to these codes, there are also building codes that must be followed when installing sediment traps. These codes vary depending on the location and type of building, but they generally require that sediment traps be installed in gas piping systems in order to prevent damage to appliances and ensure proper gas flow.

It is important to note that sediment traps should only be installed by licensed professionals who are familiar with the codes and regulations surrounding gas line installations. Improper installation of sediment traps can lead to gas leaks, fires, and other safety hazards.

To ensure compliance and safety, it is recommended that you have your gas line sediment traps inspected regularly by a licensed professional. This will help to identify any potential issues and ensure that your gas system is functioning properly.

Gas Line Sediment Traps and Appliances

If you have gas appliances in your home, it’s important to understand what a gas line sediment trap is and why it’s necessary. Sediment traps are designed to prevent sediment from entering the gas valve or burner area of an appliance, which can cause damage and even create a safety hazard.

Gas line sediment traps are required on all gas appliances, including pool gas heaters and gas fireplaces. However, there are some exceptions. Illuminating appliances, such as gas lights, do not require a sediment trap. Neither do outdoor grills, ranges, or clothes dryers.

Sediment traps should be installed downstream of the appliance shut off valve and as close to the appliance inlet as possible. This helps ensure that any sediment or debris that enters the gas line is caught before it can cause damage to the appliance.

When installing a sediment trap, it’s important to use the correct size and materials. A gas sediment trap kit, which includes a forged brass gas ball valve, tee fitting, cap, and gas flex line, is a good option. This kit eliminates the need for repetitive field fabrication, saves labor, and reduces leak paths.

It’s also important to have your gas appliances inspected regularly to ensure that the sediment trap is functioning properly. A qualified inspector can check for any signs of damage or wear and tear and make any necessary repairs or replacements.

Materials and Lifespan of Sediment Traps

When it comes to sediment traps, the materials used in their construction play a crucial role in their effectiveness and lifespan. Two common materials used in sediment traps are carbon steel and stainless steel.

Carbon steel is a popular choice due to its affordability and durability. However, it is susceptible to corrosion, which can reduce its lifespan. Stainless steel, on the other hand, is more expensive but highly resistant to corrosion, making it a great choice for long-lasting sediment traps.

The lifespan of sediment traps is another important factor to consider. Sediment traps typically last for 24 months or less, after which they need to be replaced. This is because they can become clogged with sediment over time, reducing their effectiveness.

Regular maintenance is crucial in extending the lifespan of sediment traps. It is recommended to clean them every six months to prevent sediment buildup and ensure they continue to function properly.

In addition to the materials used and maintenance, the design of sediment traps can also impact their lifespan. Sediment traps with larger volumes have longer detention periods, allowing them to remove more sediment before becoming clogged.

Troubleshooting Common Issues

Gas line sediment traps are designed to prevent sediment from entering your gas line and causing issues with your gas appliances. However, even with a properly installed sediment trap, issues can still arise. Here are some common issues you may encounter and how to troubleshoot them:

Clogs

If you notice a decrease in gas pressure or your gas appliances are not functioning properly, it could be due to a clog in your gas line. Sediment traps are designed to catch sediment before it enters your gas line, but they can still become clogged over time. To troubleshoot a clog, try the following:

- Turn off your gas supply and disconnect the sediment trap.

- Inspect the trap for any visible sediment or debris.

- Clean the trap and reattach it to your gas line.

Leaks

Gas leaks are a serious safety hazard and should be addressed immediately. If you smell gas or suspect a leak, follow these steps:

- Turn off your gas supply and evacuate your home.

- Call your gas company or a professional plumber to locate and repair the leak.

- Do not attempt to fix the leak yourself.

Corrosion

Over time, the metal components of your sediment trap can corrode, leading to leaks or other issues. To troubleshoot corrosion, try the following:

- Inspect your sediment trap for signs of rust or corrosion.

- If corrosion is present, replace the trap with a new one.

Moisture

Moisture can accumulate in your sediment trap, leading to corrosion or other issues. To troubleshoot moisture, try the following:

- Inspect your sediment trap for signs of moisture, such as rust or corrosion.

- If moisture is present, drain the trap and inspect it for any damage.

- Consider installing a moisture trap in addition to your sediment trap to prevent future issues.

Clogging

In addition to sediment, other debris can accumulate in your sediment trap and cause clogs. To troubleshoot clogging, try the following:

- Inspect your sediment trap for any visible debris, such as leaves or dirt.

- Clean the trap and reattach it to your gas line.

- Consider installing a filter in addition to your sediment trap to prevent future clogs.

Additional Resources and Learning

If you want to learn more about gas line sediment traps, there are plenty of resources available to help you. Here are some tips and tricks to help you get started:

- Check out the U.S. Environmental Protection Agency’s PDF on sediment traps. It provides a great overview of how sediment traps work and why they’re important.

- Structure Tech Home Inspections offers a detailed explanation of sediment traps and how they prevent sediment from getting into gas valves or burners. They also provide some great photos that show what sediment accumulation can look like over time.

- Inspectagator offers a helpful guide on how to properly install sediment traps. They explain the most common mistakes and provide tips on how to avoid them.

- Heaterview provides a step-by-step guide on how to install sediment traps on gas lines. They explain why sediment traps are important and provide tips on where to install them.

- If you’re interested in learning more about gas line safety and maintenance, the National Association of Home Builders offers a great resource on gas line safety. They cover everything from how to detect gas leaks to how to properly maintain gas appliances.

FAQ: Gas Line Sediment Trap

What is a sediment trap on a gas line?

A sediment trap, also known as a drip leg, is a device that is installed on a gas line downstream of any point where solid particles may accumulate. The trap is designed to capture these particles while allowing gas to flow freely through the line. It is typically a short section of pipe with a capped end that is installed at a low point in the gas line.

Does a gas line need a sediment trap?

Yes, a gas line should have a sediment trap installed to prevent damage to gas appliances and ensure that they operate efficiently. Sediment traps are required by many building codes and gas utility companies.

What gas appliances need a sediment trap?

Most gas appliances, including furnaces, water heaters, and stoves, require a sediment trap. The trap helps to prevent damage to the appliance by capturing any solid particles that may be present in the gas line.

Is a sediment trap required by code?

Yes, sediment traps are required by many building codes and gas utility companies. The specific requirements for sediment traps may vary depending on the location and type of gas line.

When did sediment traps become code?

Sediment traps have been required by many building codes and gas utility companies for several decades. The specific requirements for sediment traps may vary depending on the location and type of gas line.

How much does it cost to install a sediment trap on a furnace?

The cost of installing a sediment trap on a furnace may vary depending on the location and complexity of the installation. In general, the cost of installing a sediment trap is relatively low compared to the potential cost of repairing or replacing a damaged gas appliance. It is recommended to consult with a licensed professional to determine the specific cost of installing a sediment trap on your gas line.